Star-EDS™(Economic Die System)

Evolving QDC die set

Economic Die ChangeRapid Die Change System

● Are you satisfied with it?

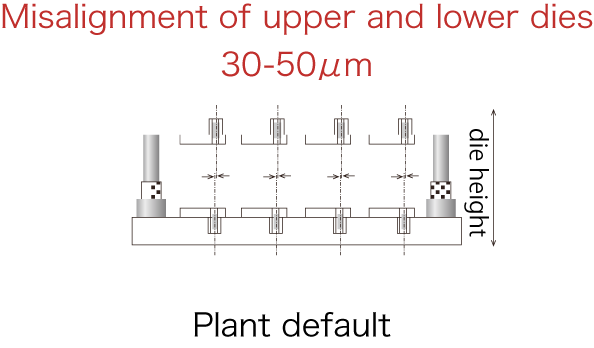

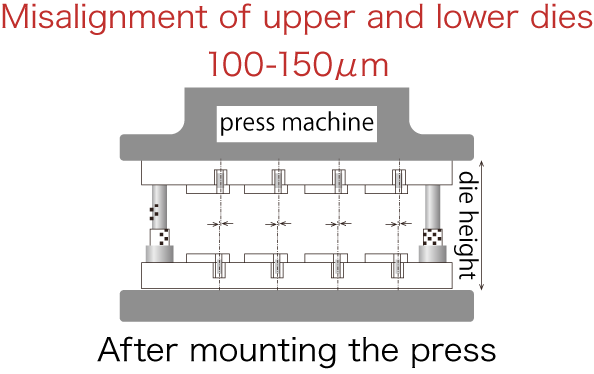

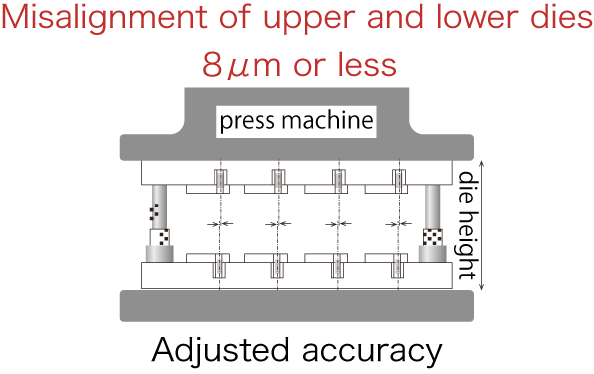

Regarding the accuracy of

upper and lower die alignment for your cassette type die set...

● Did you know?

Even with older press machine,

high precision can be achieved by setting up cassette-type dies!

What is the System?

" Star-EDS™" is a system that realizes "shortening setup times" and "same positioning accuracy even if anyone sets up."

We have a lineup of EDS presetters and EDS baseplates.

※ Also known as "QDC(Quick Die Change)", " Rapid Die Change System"

Star-EDS™ System Features

- Unlike an integral mold built into a traditional die set, the mold attaches to a small baseplate and attaches it to a EDS die set.

- Positioning is completed simply by turning the knob by hand.

- The base plate can be easily tightened by manual clamping with a mechanical system or auto-clamping with hydraulic pressure.

- By using a dedicated base plate, dies can be easily attached and detached not only from a single die set, but also from a large die set or a multi-process die set.

Conventional QDC (cassette-type) die set

Using the Star-EDS™System

Obtaining patents

- ● Our engineers coordinate directly at the site.

(actual costs will be charged) - ● Depending on the die structure,

it may not be possible

to use the Cassette Type.

Please contact us for details.

Achieve total cost reduction!

-

Point 1

Reduction of setup time

The time required for aligning the

upper and lower dies is

reduced,enabling quicker

die changes. -

Point 2

Improvement of productivity

The ability to simplify mold design

allows more products

to be produced. -

Point 3

High-quality production

High quality is made possible by the

high accuracy of the upper and

lower die position of the

cassette type die set. -

Point 4

Cost reduction

Reducing the weight of the mold

reduces the cost of

mold making. -

Point 5

Environmental contribution

Higher quality thanks to higher

precision reduces scrap

and saves resources.