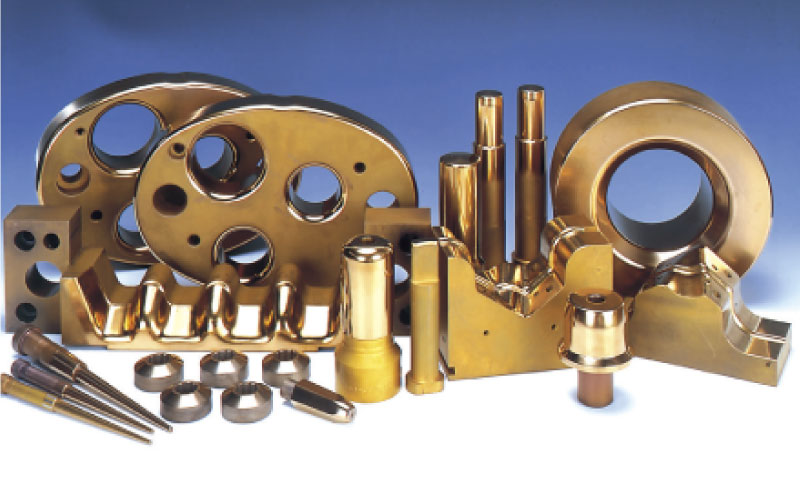

SURFACE TREATMENT

We propose "optimal" products with a diverse range of technologies and a lineup.

Our surface treatment lineup

-

Salt Bath Nitriding PS(Prevents Scoring and Scuffing)/PW(Prevents Wearing) treatment

Deep nitrided layer is formed by low-temperature nitriding and short-time treatment using in-house developed salt bath agent.

-

CERAC-C (CVD)

A high-purity gaseous raw material is chemically reacted in a high-temperature state of about 1000℃ by a decompression-type facility, and an ultra-hard compound (ceramic) with little defects and impurities is coated.

-

CERAC-P (PVD)

Carbide compound (ceramic) is coated at low temperature (500℃ or less) by ion plating.

-

Gas Sulfonitriding Treatment (PSG)

Taking advantage of the features of gas nitriding, complex shapes such as deep holes, stop holes, and fine holes can also be treatment.

-

PX (Plasma Nitriding)

There is almost no change in the nitrided surface without the compound layer, and the properties are good.

-

AMINIT SS (Nitriding added Compressive Stress)

Improved heat check resistance of die casting type by applying high compressive residual stress.

-

High-Ten CERAC (Physical Vapor Deposition)

PVD treatment suitable for cold press forming including High tensile strength steel by coating flaw (pinhole, droplet) control.

-

SX-CERAC (Compound PVD)

Ultrafine particle peening is combined with various PVD coatings to achieve a long service life through the synergistic effect of the sliding property of the hard film and the excellent holding force of the processing oil.

-

AMICOAT-C (Compound PVD)

By combining various PVD coatings with a special nitriding treatment, peeling resistance comparable to that of CVD coatings and a long service life can be achieved.

-

AMICOAT-DP (Compound PVD)

Next-generation new coatings to prevent burning and adhesion of molten aluminum. Dramatically improved aluminum erosion damage resistance and wetting resistance.

-

AMICOAT-H (Compound PVD)

New coating that meets the characteristics of warm and hot dies. Abrasion resistance is achieved even at high temperatures.

Our features and strengths

■ We have a variety of surface modification technologies that can be used for a variety of applications.

Seepage diffusion method

- PS・PW (Salt bath Nitriding)

- PSG (Gas Sulfonitriding Treatment)

- PX (Plasma Nitriding)

- AMINIT SS (Nitriding added Compressive Stress)

Deposition coating method

- CERAC-C(CVC)

- CERAC-P(PVD)

- High-Ten CERAC

- SX-CERAC

- AMICOAT-C

Improved wear resistance by combining the base nitriding process, which is ideal for PVD treatment - AMICOAT-DP

Coating for die casting dies - AMICOAT-H

High-performance coating with high hardness and heat resistance